Machine-Intelligent Pipe Inspection Technology Identifies Defective Service Tap Connections Missed by CCTV Inspection

New machine-intelligent equipment has become a game-changer in how leaks can be precisely located & measured in sewer systems.

Study Finds CCTV Cannot Reliably Judge Defective Tap Connections That Leads to Overstating the Responsibility of Property Owners as a Main Cause of Infiltration

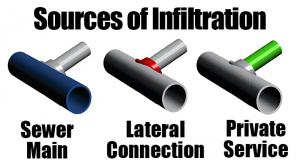

Customer service taps are where homeowner's pipes are connected to the municipal sewer system and which are typically the responsibility of the local water or sewer utility.

The recent study involved a large EPA Region IV water utility that compared results from machine-intelligent probes to legacy Closed-Circuit Television (CCTV) inspection techniques for 24,383 linear feet (LF) of pipe consisting of eighty-eight (88) sewer mains having 283 customer service tap connections.

Machine-intelligent inspection using Focused Electrode Leak Location (FELL) technology measured leaks contributing to inflow and infiltration (I/I) at 178 taps, or 63% of all connections, compared to only 5 defective taps identified by certified camera operators using CCTV, or just 2% of all service connections.

More importantly, FELL inspection also quantified the potential I/I flow rate from the 178 defective connections at nearly 1,400 gallons per minute (GPM).

Pipe materials in this comparison study were limited to Polyvinyl Chloride (PVC) and Vitrified Clay Pipe (VCP). The PVC rehabilitated pipe represented 80% of all the service connections, and VC pipe the remaining 20%. However, the newer PVC represented 98% of the potential I/I flow from defective customer taps, indicating poor construction and lackluster quality assurance testing using CCTV visual inspection.

"Studies like this are invaluable to support all utilities and their critical CAPEX decisions," stated Michael Condran, PE, Vice President, Electro Scan Inc.

"Rate payers are willing to accept reasonable service fee increases if they can be assured that rehabilitation and renewal programs are selected using reliable & unbiased data and that proper quality control programs are in place," stated Condran. "Machine-based probes provide that assurance."

All CCTV operators in this study were certified by NASSCO, Inc.'s Pipeline Assessment Certification Program (PACP). All automated machine-based testing was completed in accordance with ASTM F2550.

Closer examination found that sewer main defects such as defective joints and cracks, contributed approximately 700 GPM, or 34% of total potential I/I flow, while defective tap connections represented 66% of potential I/I.

Why the fascination with customer service tap connections?

"Because CCTV contractors are increasingly being found to rate tap connections as 'OK' or Factory Tap Active, when in fact, they leak," states Chuck Hansen, Chairman, Hansen Analytics LLC.

"If CCTV contractors also under-report leaks at pipe joints in the sewer main, property owners by default may be wrongly blamed for causing I/I when faulty visual inspection of sewer mains is the real culprit," states Hansen.

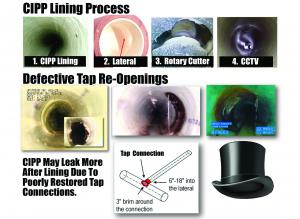

Recent studies show that service connections are also responsible for a large number of leaks in Trenchless Cured-In-Place Pipe (CIPP) lining projects.

During sewer relining work, contractors must temporarily cover over existing customer service connections. As a result, these openings must be precisely re-cut to properly re-establish services without causing unintended I/I flow at the service connection.

As precipitation percolates through the soil, water can re-enter sewers at their weakest point. Resulting in little, if any, I/I reduction despite costly repairs and/or relining projects.

If service connections didn't leak before rehabilitation, then they shouldn't leak after rehabilitation. But, If contractor damage occurs, a higher rate of infiltration may result compared to leakage rates before repairs were completed.

The current study validates earlier studies with the utility owner unaware of the consequences of poorly restored customer services.

In addition to a CCTV operator's inability to identify defective taps, camera-based 360-degree optics, lasers, and newer Light Detection and Ranging (LiDAR) technologies are also unable to differentiate superficial cracks from cracks that go through a pipe wall. Resulting in under-reporting potential sewer main-related pipe leakage.

The PACP coding standards for CCTV inspection also do not quantify infiltration rates in standard gallons per minute or liters per second measurements. Instead, general code descriptions are used that have no assigned potential I/I values attributed to specific defects, construction features, or locations.

If no defects are found in sewer mains using CCTV inspection, infiltration is often assumed to come from the property owner's private lateral.

While data analytics are widespread among most innovative water utilities and construction companies, a host of emerging technologies, like FELL, are causing disruption in the market as the overall digitization of the water sector seeks out solutions with the highest rate of return and financial payback.

Separately, Hansen is conducting leak assessment projects around the world, comparing FELL with other existing and emerging technologies, while also providing QA/QC reviews of standalone inspection projects.

Recently, utilities have begun asking 'why high I/I rates continue after tens of millions have been spent on complex repair & rehabilitation programs?'

In 2019, Hansen evaluated nearly 800,000 LF of CCTV inspection from a single utility in EPA Region VII, along with over 30,000 LF of post-rehabilitated sewer mains. In that study 42% of all sewer tap re-connections were found to have defects contributing to I/I.

Another significant finding was that CCTV inspection results indicated a near-watertight sewer network, with 99.2% of all joints having no defects contributing to I/I. Observed results by the owner documented the relatively small I/I reduction of less than 20%. The CCTV results mislead the owner as to the rehabilitation effectiveness.

Results from Hansen's comparative machine-based studies will be presented at this year's Texas Water 2020, available online to conference attendance the week of July 13 and sponsored by the Water Environment Association of Texas (WEAT) and Texas American Water Works Association (TAWWA).

ABOUT HANSEN ANALYTICS LLC

Founded in 2006, Hansen is dedicated to aggregating municipal and investor-owned utility data to streamline decision support. Founding Hansen Software in 1983 (later called Hansen Information Technologies), principals of Hansen Analytics are pioneers in municipal & utility asset data science, artificial intelligence, machine learning, and utility management helping thousands of cities and utilities create digital twin environments to help decipher and interpret operational, financial, and capital efficiencies.

Janine Mullinix

Hansen Analytics LLC

+1 916-779-0660

email us here

Visit us on social media:

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.